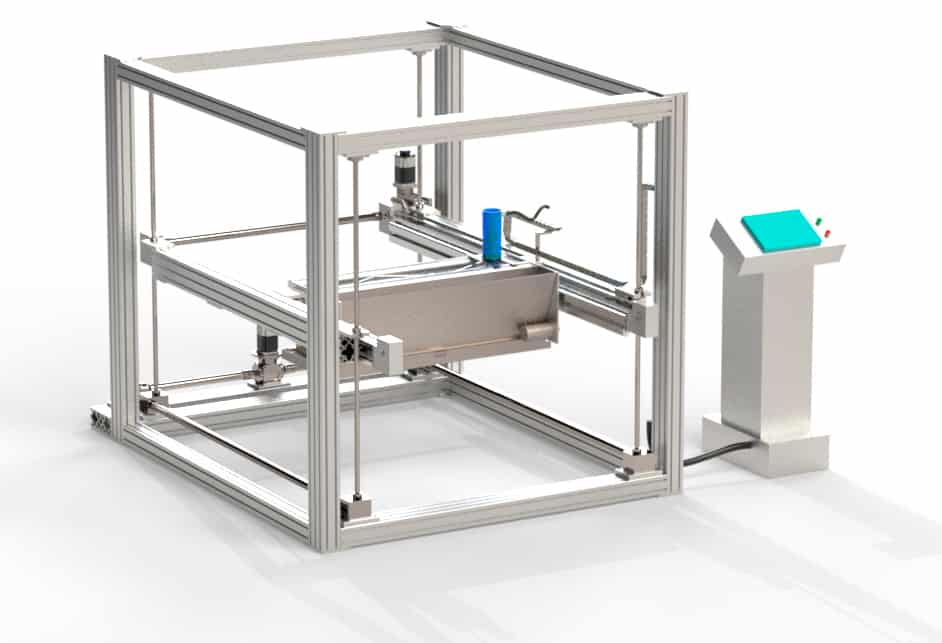

Desamanera 3D printing technology is designed for inert materials use, in very fine particle size. The production consolidates the powder through a chemical reaction and the printed material appears as a stone.

For us, the environment respect is fundamental: the aggregates we use most are marbles, dolomites, stones, sands coming from the other processes waste; the binder is an our patented formulation which includes only natural inorganic materials and which can replace Portland cements use.

However, the technology allows the choice of other materials according to the chemical, physical and performance characteristics, required for specific uses.