WITH 3D PRINTING WILL YOU WALK ON THE CEILING OR ON THE FLOOR?

Landscape House is a project of a pool of Dutch companies coordinated and directed by Janjaap Ruijssenaars, owner and founder of the Studio “Universe Architecture” of Amsterdam.

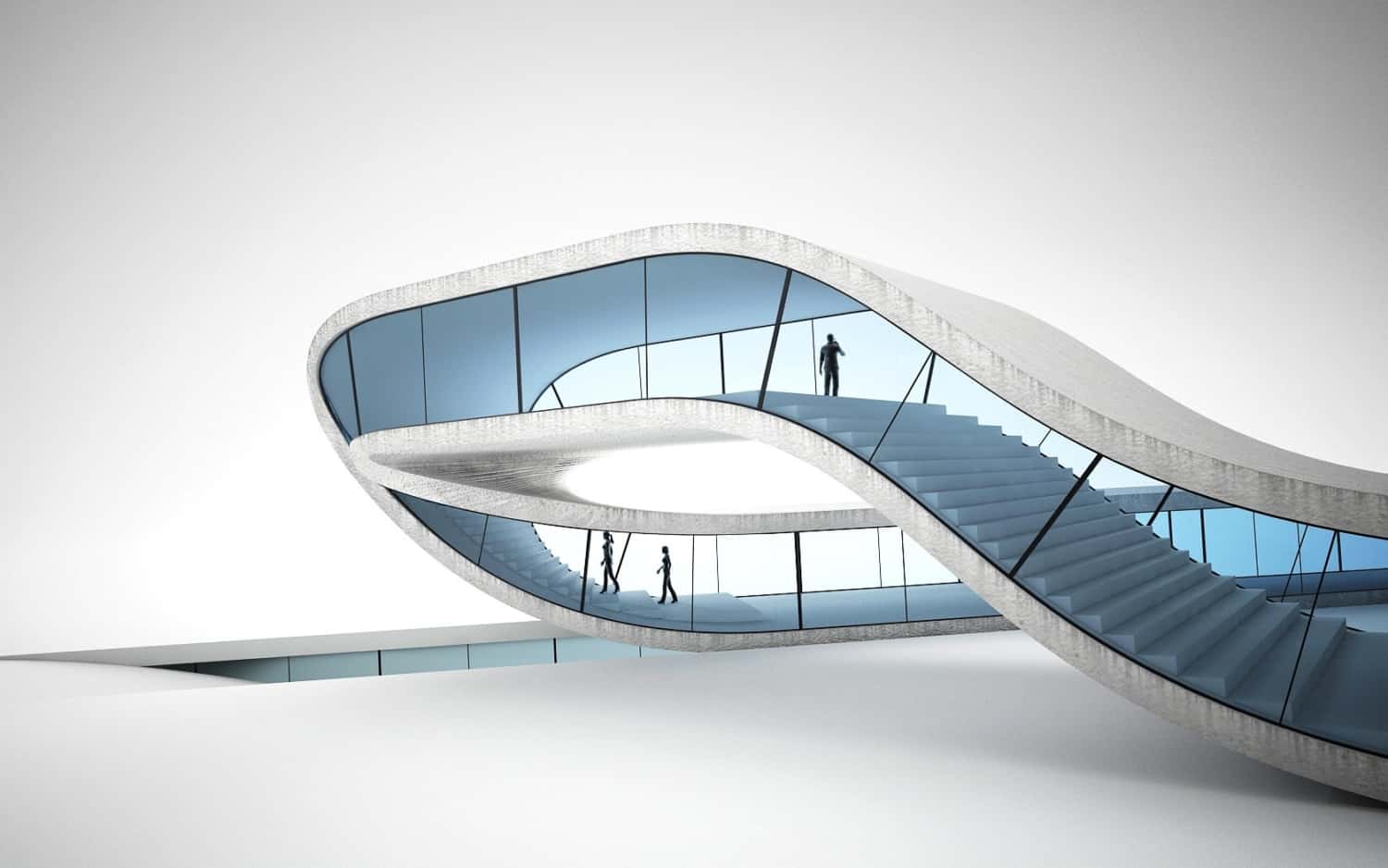

Landscape House is an example of how 3D printing can change the way we design buildings. How? I’ll explain that. If to build a house we used to think in terms of concrete and bricks, giving to the various spaces and surfaces a precise name (ground floor, first floor, ceiling etc.) well, then the my question is .. try to do it here, in this type of construction, where space is a continuum. It is not easy right? Obviously this is only apparently a request, the main aim is to understand how the project Landscape House sheds new light on the great potential of 3D printing, and gives a chance to propose design solutions never seen until now.

The big advantage is that you can print shapes directly as they have been conceived and designed. That’s right! So while printing piece a wall, you can also print at the same time stairs or pipelines for electricity ..in short, all that will be expected from the CAD project (Computer Aided Design), which will be later entirely converted into STL (Stereo Lithography interface) format, ready to be printed. Did we arouse your curiosity? Ok, let’s look into. Here we’ll explain methods of implementation, goals and ideas behind this “house without an end.”

• WHAT

Landscape House is inspired by the forms of a Mobius strip; and not only your eyes will follow its structure in loop. Everything that is not transparent to the eye will be printed: from the complex twists of stairs, to the hollow structures of ceilings and floors to be reinforced, to pipelines for water and electricity. The 5 mm voxel of the printer (its cubic unit) will surely have an impact on the texture of the building: the interior surfaces will be very probably further finished to smooth the print material, while externally we think to we will leave intact the finished result.

• HOW

Surely you already know how a normal printer works. The method of functioning is almost the same, it only gets bigger, with a different “ink”. We will find mineral material that will be bound and solidified by a liquid agent released from the nozzles during printing.

The nozzles that will move in three dimensions on the mineral material will solidify blocks from 6×9 meters, which will be later used to assemble the house, from the bottom to the top.

If it is not clear yet the reason behind this particular form of the house it will be soon revealed, now we will better understand why 3D printing was chosen.

• WHY 3D PRINTING

You will surely have noticed that in the process of production of the models there is always a point of beginning and a point of end. The spaces are well defined. But in this particular form the building has an interior that twists on itself, becoming external, and vice versa, so technically and practically the inside and the outside are never-ending. The 3D printing technology makes it possible to recreate this type of surface and effect with maximum precision. Janjaap Ruijssenaars, as a designer first emphasized the importance of using these methods and techniques of 3D printing for this kind of idea.

But what really pushed to start the Landscape House project? And why a Mobius strip?

Imagine a horizon that merges into curves of the surrounding hills. Hills that become valleys and seas which are at one with the mainland. Here it is. The creatives of Universe Architecture (which Ruijsennaars is founder) has been inspired by a beautiful landscape site in Ireland, chosen for construction. The main message they wanted to convey with Landscape House is a house that looks like the never-ending surrounding landscape. A continuous space? How? The first step was to take a thin strip of paper that has been twisted and wrapped several times and in different ways on itself. Thus has been created a complex form for the structure without a beginning and end, whose shape and whose curves were in harmony with the environment.

Innovation. Integration with the landscape. Creativity. New challenges that 3D printing faces with structures never seen before. You can read another example in this article.

Photogallery

Published on 9th September 2015