ADMIN 4D, THE SMART MANUFACTURING OF THE FUTURE

Industrial revolutions have from time to time radically changed societies and everyday life.

Innovations in production processes and new technologies are leading us to intelligent and effective management of resources, improved services and greater well-being. Cities become smart and the Internet of things (called IoT) is becoming more and more widespread.

We are inside the fourth industrial revolution: the digital transformation allows manufacturing companies to develop new ways of innovating and producing, offering mass customization and reducing waste to a minimum; a new way of thinking about the factory, new relationships between suppliers, producers and customers, between man and machine.

The exchange of information between physical and digital systems takes place thanks to the so-called enabling technologies: internet of things, big data, 3D printing, high performance innovative materials, which are environmentally friendly and respectful of Nature.

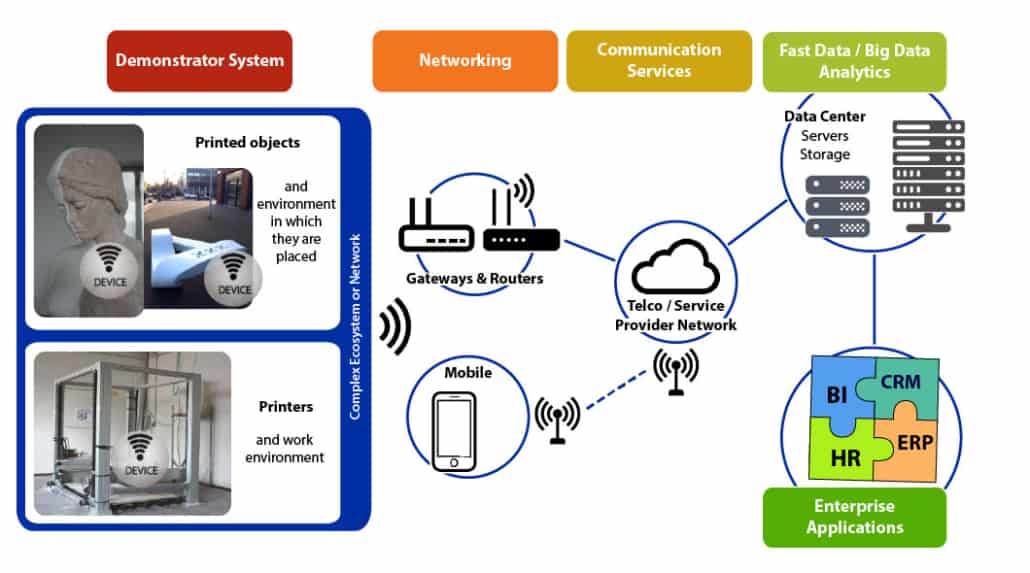

ADMIN 4D is a project promoted by the IMPROVENET network, a Veneto cluster of public and private subjects, including manufacturing companies, suppliers of highly innovative services and subjects that carry out research activities, co-financed by the Veneto Region – ROP ERDF 2014- 2020. It is a strategic project in the field of RIRs, special networks recognized by Veneto region (keep reading for more info about them), because it involves and develops some technologies which characterize Industry 4.0, in particular the Smart Manufacturing, and enhances the production areas of sectors of excellence: 3D Printing of minerals in large dimensions, Engineering of materials and their re-use, Sensors applied in the Internet of Things, Mechanics and Mechatronics, Big Data Analytics, Cloud Computing and CyberSecurity.

The project involves the development of an innovative production system that collects many information, technical and chemical ones and about the composition of the materials. These info comes from different operational parts of the 3D printers, from the raw materials used and from the materials that make up the finished products. The system processes them in real time through specificallly developed algorithms.

There are two scientific and industrial objectives:

1. The production of objects that, thanks to 3D printing, hide specifically designed sensors inside them. The materials used are natural and biocompatible; they are recycled materials as they come from waste from other processes; they are low-cost materials but engineered to become high performance materials. The integrated sensors monitor and optimize the performances of the object itself.

This 3D printed element was made during a sensor test phase.

Several elements were printed with the same shape and different dimensions, just like Russian dolls: we inserted the sensor to be tested inside them.

2. The second objective is the heart of ADMIN 4D, that is the realization of the first production machinery called “demonstrator system”, starting from our 3D printers in large size for Minerals.

The overall system will produce and collect information through the sensors that will govern it; thanks to the real-time analysis of the big data collected, the demonstrator system will be intelligent and autonomous, capable of correcting and optimizing production in real time, without human intervention.

Through the information gathered by the sensors, it will be able to evaluate the consequences of each individual variation, both in the composition of the materials and in the dynamics of the production process, and will decide independently when to make changes, both to correct any errors and to further optimize the final product.

Everything will work as a function of pre-established rules, which will allow the control component of the system to communicate to the command component the actions to be carried out in the presence of any difference in the process, programmed or unexpected.

Graphics of the elements of the Demonstrator System and of the transmission and data collection process planned by ADMIN 4D.

The project involves 7 partners: 3 companies and 4 Research Centers.

- Desamanera, leader of the project, provides its technology and know-how regarding 3D printing. It also houses the prototype of the demonstrator system.

- The team of the Department of Industrial Engineering (DII), of the University of Padua, coordinates R&D activities, the optimization of materials and their relationship with the sensors that will be inserted.

- Mas Elettronica, specialized in the sensor sector, defines which types of sensors must be realized.

- The IEIIT – the Institute of Electronics and Information Engineering and Telecommunications, a CNR research facility, studies data transmission equipment with particular attention to wireless technology.

- Dataveneta Computers defines, develops and manages cloud-based infrastructures where big data is collected and analyzed by Statwolf technologies.

- The team of the Department of Environmental Sciences, Computer Science and Statistics (DAIS), of the Ca’ Foscari University of Venice, will model the software architecture of the “demonstrator system” with a special consideration for information security.

- T2i, technology transfer and innovation, is the agency promoted by the Chambers of commerce of Treviso, Verona and Venice that deals with certifications, the study of the market and the dissemination of results.

The 7 partners together established a RIR, IMPROVENET.

RIR is an acronym for the italian Reti Innovative Regionali, i.e. regional innovative networks. They are systems of public and private subjects, also belonging to different sectors, whose partners collaborate synergistically and develop important projects for the regional economy, thanks to the specific skills of each one.

Improvenet in particular aims to increase the competitiveness of the partner companies, and enhance, promote and support innovation, technologies and methodologies of the fourth industrial revolution. The 3-year project, 70% funded by Veneto Region, started in November 2017 and will be completed in October 2020.

ADMIN 4D is an intervention carried out thanks to the ROP Regional Operational Programme funding – Objective “Support to RD activities for the development of new sustainable technologies, products and services ” ERDF European Regional Development Fund 2014-2020.

In this new world, the ADMIN 4D project involves specialized excellence to put man at the center: he is creator and manager of intelligent machines, which communicate in real time with the objects and the environment that surrounds us; their performances give a real benefit to man, improving the quality of life.

Published on 14th October 2019